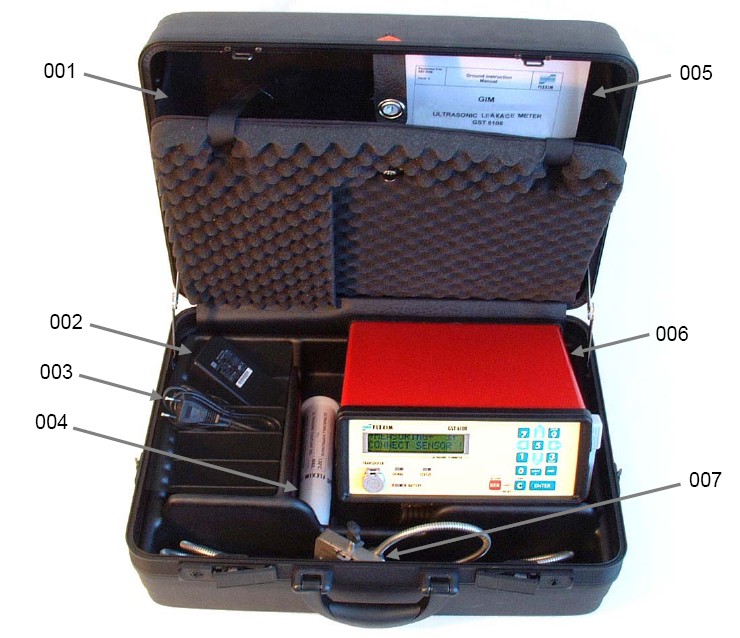

| Item | Description | Quantity |  |

| 1 | Data transfer kit | 1 | |

| 2 | Power supply and battery charging unit, 110 V AC – 220 V AC (without power cord) |

1 | |

| 3 | Power cord Europe incl. universal adapter | 1 | |

| 4 | Coupling compound tube | 1 | |

| 5 | User’s manual English | 1 | |

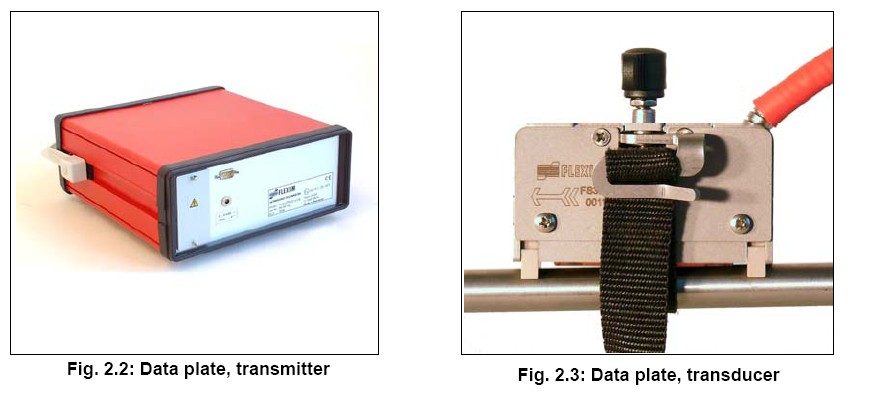

| 6 | Transmitter GST 6108 | 1 | |

| 7 | LEAKAGE transducer FS3N7 | 1 | |

| 8 | Carrying case | 1 |

610007AB

超声波流量计(ULTRASONIC LEAKAGE METER GST 6108)

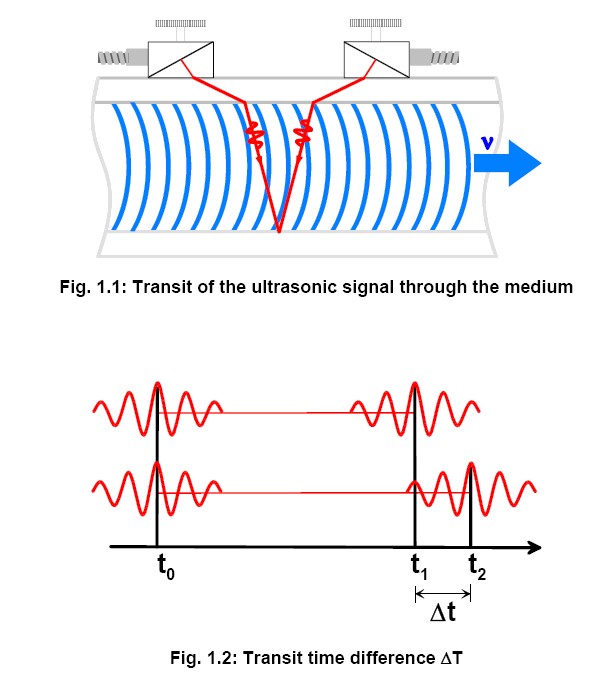

| The LEAKAGE meter measures the leak rate in hydraulic systems according to the ultrasonic transit time difference principle. The measurement is non invasive, absolutely no intrusion in the pipe system is needed. Ultrasonic signals are sent by the transducer into the pipe, reflected on the inner pipe wall of the opposite side and come back to the transducer. These signals are emitted alternatively in the direction of flow and against it. Because the medium in which the signals propagate is flowing, the transit time of the sound signals propagating in the direction of flow is shorter than the transit time of the signal propagating against the direction of flow. The transit time difference T is measured and allows the determination of the average flow velocity on the propagation path of the ultrasonic signals. A profile correction is then performed to obtain the average flow velocity on the cross-section of the pipe, which is proportional to the volume flow rate. The LEAKAGE meter tests with its special electronics the incoming ultrasonic signals for their usefulness for the measurement and evaluates the plausibility of the measured values. The integrated microprocessors control the complete measuring cycle, eliminating disturbance signals by statistical signal processing techniques. |

|